Description

Technologies

K2 SANDWICH MEMBRANE

Purity and precision of sound

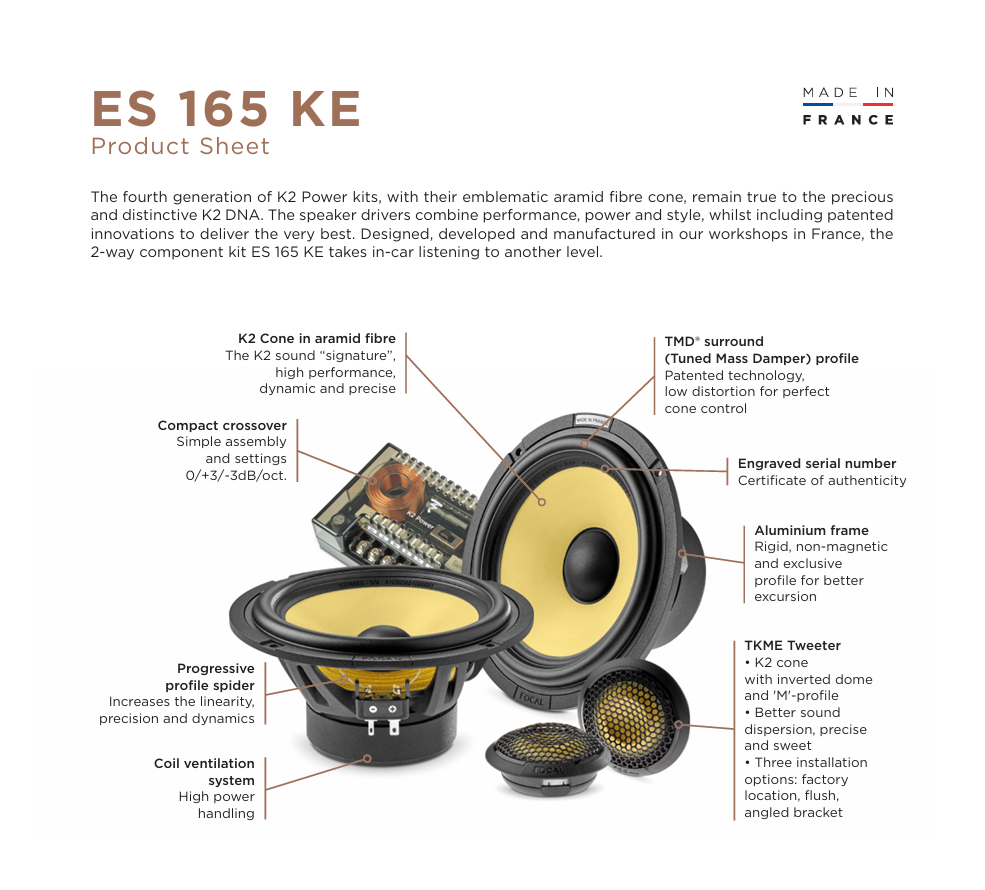

The diaphragm, the key component of a loudspeaker, is at the heart of our acoustic engineers’ research. Shape and materials are essential for high-fidelity reproduction. In 1986, our teams unveiled an aramid fibre sandwich membrane, recognizable by its unique yellow color. It has been extensively renewed over the years, while retaining the characteristics that made it such a success. Today, it consists of an ultra-light foam core sandwiched between a layer of aramid fibre and a layer of glass fibre. It combines the three key factors of a loudspeaker membrane: rigidity, lightness and damping, for a precise, dynamic and uncolored sound.

TMD SUSPENSION

Stabilized surround, eliminates vibrations

While our engineers are experts in the development of exclusive diaphragms, they also innovate in all the components that make up the loudspeakers, such as the surround that connects the diaphragm to the frame, the performance of which must be mastered. Introduced in 2015, Tuned Mass Damper (TMD) technology with harmonic damping consists of the addition of finely positioned toroidal weights to stabilize the surround for even greater sonic neutrality. This technology enhances the midrange and the erratic behavior of the surround between 1 kHz and 2 kHz.

OPTIMIZED FILTERS

A high-performance soundstage

Every element of a loudspeaker is important. Our engineers focus on every component, including the crossovers. Crossovers provide each loudspeaker with a signal that enables it to work at its best in the frequency range for which it is designed. For K2 Power kits, all crossover components have been specifically selected and optimized to better control heat dissipation effects, and manage channels and soundstage with reliability and performance.